IoT Gateway Adapter

By adopting this product, converting control system to IoT, that is used to usually hesitate in terms of cost and performance, is easily possible in short period of time.

Concept

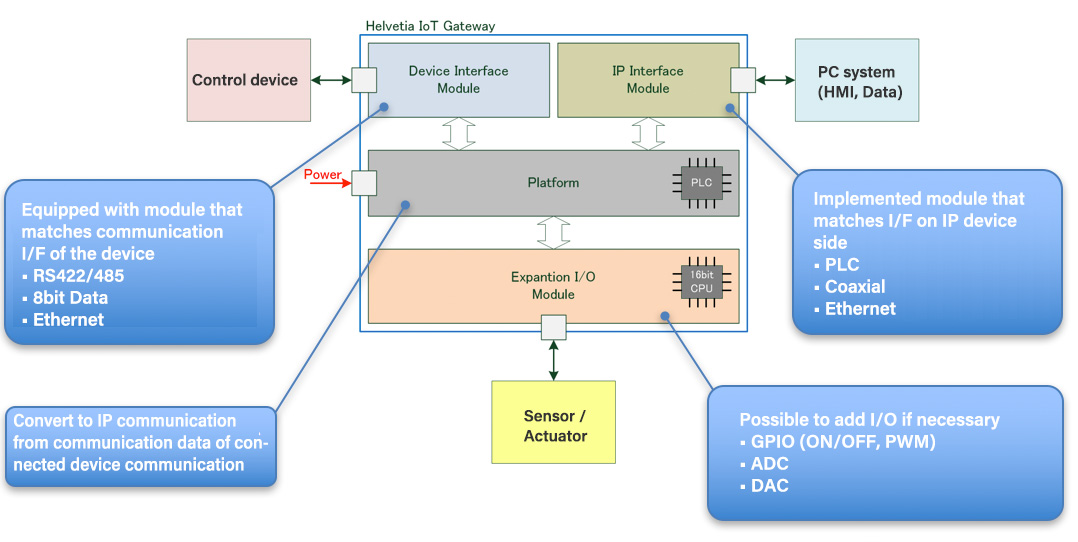

• Various control devices of equipment can be easily converted to IP.

• Multi I/F that can be customized are equipped, that can make realize various control devices of equipment to IoT with low cost and short time.

Features

1. Promoting the IoT of control equipment

• The following standard I/F are equipped in order realizing IoT. It is easily possible to be IoT device just by connecting.

[Equipment side I/F]

• Serial I/F(RS422/RS485)

• 8bit parallel I/F(for smart meter)

• Ethernet

[IP side I/F]

• PLC (Power Line Communication)

• Coaxial cable

• Ethernet (RJ45)

* I/F other than above mentioned will be supported sequentially(LON, Device-Net etc.) and it is also possible to support customed I/F.

2. Long-distance communication is capable

• Since the communication using PLC technology is converted IP transmission by power cable or coaxial cable is possible, that makes possible to long-distance communication of 2000m or more between devices.

3. I/O control is possible by using option

• The sensor and the actuator can be controlled directly from this device. In addition, since16bit microprocessor is equipped for I/O control, various I/O controls are possible.

[Equipped I/O]

• Digital I/O : ON/OFF,PWM

• Analogue I/O : ADC, DAC

4. Monitoring the operating status and setting the device up form web is possible

• Remote setting/displaying status is possible even if it is placed in area where work is difficult, such as behind the celling etc.

The conventional problems and solutions

By adopting this product, converting control system to IoT, that is used to usually hesitate in terms of cost and performance, is easily possible in short period of time.

| Items | Conventional Problems | Solutions by VPLC-1000 |

| IP conversion method | Install PROTOCOL CONVERSION DEVICE | Connect or built-in VPLC-1000 |

| IP realization | Develop special communication module | Equip corresponding module to I/F |

| Network /Wiring length | Short (100m @Ethernet) | Long (2000m @Coaxial) |

| Network /Wiring cost | High (cascade connection by Hub) | Low (Cables only) |

| Security / Encrypt | Each equipment required | Installed (AES-128) |

| Security / Outside Attack Defense | Each equipment required | Installed (White List System) |

| PLC / Versus noise performance | weak to noises | •Communication band where little influence of noises •Improve versus noise performance by transmission output improvement |

| PLC / Communication Speed | Low speed communication | Effective rate 20-40 Mbps |

| Specifications & appearance may change without notice for improvement. | ||

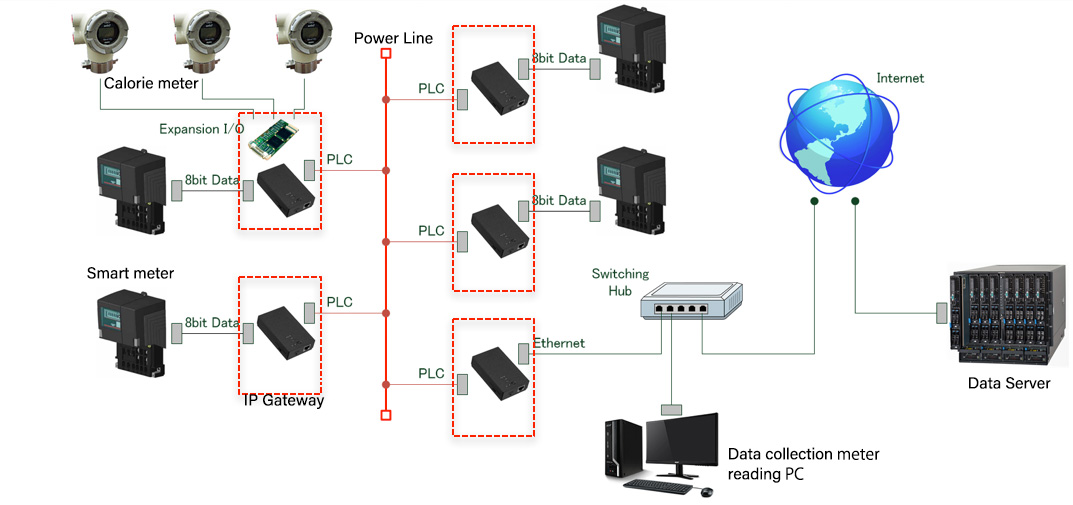

The system structure

Equipped with the necessary I/F and transformed into an IoT device just by connecting to this device. (Installing into control device is also available.)

Case study: IoT application of meter reading system

• IP conversion of smart meter data.(using the device I/F:9bit Data Module, IP I/F:PLC Module)

• After receiving the calorimeter signal by GPIO and process the data, it is converted to IP.(using the expansion I/O module)

• Inputting collection data/reading meter to the PC then meter reading operation is performed by online.

• Store the collecting data from each meter to the data server then these data can be reused as a big data.

• ⇒ IP conversion of meter reading system makes reducing the cost of meter reading operation, and energy serving control is possible by reusing collected data.